Search Here

Search Here

MISC

Parts List

Robot Forum

Chat

Member Pages

Axon MCU

Robot Books

Shop

Contact

SKILLS

How To Build

A Robot

Tutorial

Calculators

Mechanics

Programming

Miscellaneous

Robots

Space

HARDWARE

Actuators

Batteries

Electronics

Materials

Microcontrollers

Sensors

SCIENCE

Robot Journals

Robot Theory

Conferences

- gather and retrieve objects of unknown size/weight

- battery power is severely limited

- robot can be remote controlled

- allowable robot height/length/width limited

- further objects gained you more points

- time limit of 3 minutes

The ASME Student Design Competition

This 'mobipulator' robot (mobile manipulator) was built for the ASME Student Design

Competition in 2004, by me and three friends from CMU.

It was a one time only thing, because each year ASME comes up with a new competition. As such I will

not go into details about the competition and how to win it. However, I will talk about what we learned

that could be used by you as a reader, if you had a similar design problem.

As such, the purpose of this short tutorial is to demonstrate a unique method of wall climbing, and show dual functionality of a 1 DOF robot arm (not counting the gripper). Ok technically it is 3 DOF, because of the moving/rotating robot frame . . .

The rules basically went as this:

Without further boring descriptions, watch the video!

Specifications

The robot used one HS-311 servo for the actuated storage bucket,

one modified HS-805BB for the 1 DOF robot arm,

one servo for the robot gripper end-effector,

and two modified servos for the differential drive train.

The bucket was built from bended aluminum sheet metal, and the frame was both milled and CNCed out from aluminum raw material.

Specially shaped foam was used inside the bucket to keep the objects inside from rolling out while wall climbing.

-

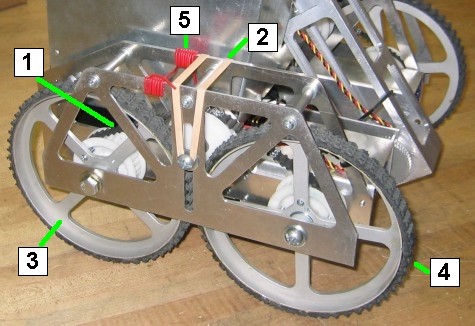

1) The wheels on each side were linked together by a timing belt, for tank style driving.

2) Rubberband was used as belt tensioner.

3) The four wheels were custom CNC machined.

4) Conveyor belt material was glued onto the wheels and grippers for its high friction properties.

5) RC reciever antenna, wrapped so as to not tangle

Control, and the Driver

The remote control was a Hitec Laser 6 (has 6 channels), each channel controlled each servo individually.

The agility of a remote control robot is very much a function of driver skill. If you ever have a remote control robot contest, driver skill can significantly affect robot performance. Practice practice practice. Know exactly how your robot will perform. Practice in realistic settings, too. We went as far as to reconstruct the test course ourselves, timing everything the robot did for speed optimization, and pushing the limits to see what the robot can do. In the video I was operating 5 servos simultaneously with two hands on the remote, a skill that took many many hours of practice to do. But it all paid off . . .

An image of a prototype version climbing a wall in our recreated test course:

You probably did not gather this from the video, but the arm was used as a balancing weight shift as it climbed the wall - not just a lifting mechanism. The claws also had to be opened up during the climb, too, so as to not break.

This early plastic-made prototype version attempted to climb the wall before we learned about the weight shift feature of the arm. Embarassingly, the basket was lowered accidently and the bot got stuck on its way over. The gripper on this version was made from nylon, and broke during the climb.

Difficulties

There were two main difficulties. The first is that the conveyor belt material, in combination with tank style driving

friction issues, made turning on carpeting very difficult. At the end of the video you will notice the robot doing weird

dancing like motions as it turns around. This is driver skill attempting to compensate for this problem. The other major

problem was arm torque. A lot of effort was put into making the arm very light yet strong enough to support the weight

of the robot while wall climbing. If you plan to make one of your own, make sure you do the

moment arm calculations first to ensure it is strong enough. We had to

gear down the servo with external gears to have just barely enough torque . . .

Results

So how did we fare? Beating out 12 teams in regionals, the team (four of us) made it to nationals in California

where we placed 7th (out of 14). Competition was really impressive and I wish I had videos to show it . . .

The SolidWorks CAD file of this robot is available for download (7.1mb). If you use the CAD (or any part of it) for your robot, please give credit and link back to this page.

Society of Robots copyright 2005-2014